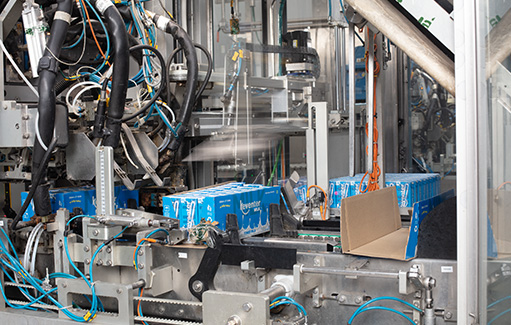

Our commitment to quality and food safety begins long before production – at the very source of our ingredients and raw materials. Our 90-acre Barasat campus in West Bengal houses Eastern India’s only UHT milk processing unit; supported by additional plants in Durgapur, Midnapore, Siliguri, and Patna. A new facility in Ranchi is underway, strengthening our reach and capability.

From sourcing to marketing, every touchpoint reflects our dedication to delivering products that are not just safe, but consistently exceptional.